How Do Sheep Survive in the Wild Without Shearing – As a General Rule, Sheep survive in the wild by being excellent climbers, having four firm hooves, and a fairly low center of gravity. Wild sheep and even some domesticated sheep survive by traversing difficult and rocky terrain that even some of the most persistent predators cannot easily climb and certainly couldn’t attack from.

How Do Sheep Survive in the Wild Without Shearing?

How Sheep Shear Themselves in the Wild? In Nature Sheep Molt twice a year to shed their wool naturally. They do not grow in size that has detrimental effects on the health status of sheep. The breed included in this category is “wild Dall sheep.” They do not need any help. They grow just enough wool to protect themselves from the cold in winter and keep them cool. When it is time, they will shed their winter coat all by themselves.

In the wild, some breeds naturally shed their wools and survived themselves. Their breeds are classified as follows;

- Must shear sheep breeds

- Natural shearer breeds

- Breeds missing wool

How do Sheep Shear Themselves in the Wild / Types of Sheep

- Wild Sheep – Bighorn – Mountain

- Domestic Sheep – Meat and Milk Sheep

- Wool Sheep

How Sheep Shear Themselves in the Wild – Based on the shearing process in sheep, they are categorized based on their wool growth. Sheep used to be reared for meat and milk, but later on, they were bred to enhance the production of wool. How Did Sheep Survive before Shearing?

Check Our Amazons Resources on Sheep

Must Shear Sheep Breeds

Why do sheep need to be sheared – Some breeds need to be shorn every year; otherwise, they will grow their wool continuously. The wool may grow in size that is two or three times the original body size of the sheep.

The survival of sheep without manual shearing mainly depends upon the type of breed of the sheep. Some breeds are selective bred to raise the sheep with heavy coats that are normally not shed, and they keep themselves growing. They need to shorn regularly. You will find a sheep three times the size of its original one. The breed included is “Merino.”

These have been selectively bred for thick heavy coats. About 30% of wool used worldwide comes from Australia, where the most commonly raised sheep, Merino. Their coats are so thick that some die of heat exhaustion during hot months. Unlike wild sheep, merinos cannot shed their fleece.

Breeds Missing Wool

What do wild sheep do about their wool – While some sheep do not have wool at all; rather, they have hair on their body. And these breeds shed their hair seasonally. There is no concept of sharing in these types of breeds. They constantly replace their hair with new ones with each changing season.

Mulesing

When domesticated sheep cannot shed their fleece themselves, their wool will grow longer while flies lay eggs in their skin’s moist folds. The hatched larvae can eat the sheep alive.

To prevent this from happening, ranchers will perform an operation called mulesing. Without anesthesia, large strips of flesh are cut off the backs of lambs and around their tails.

While considering the natural shearing method of sheep, some terms must be understood.

Shearing Domestic Sheep

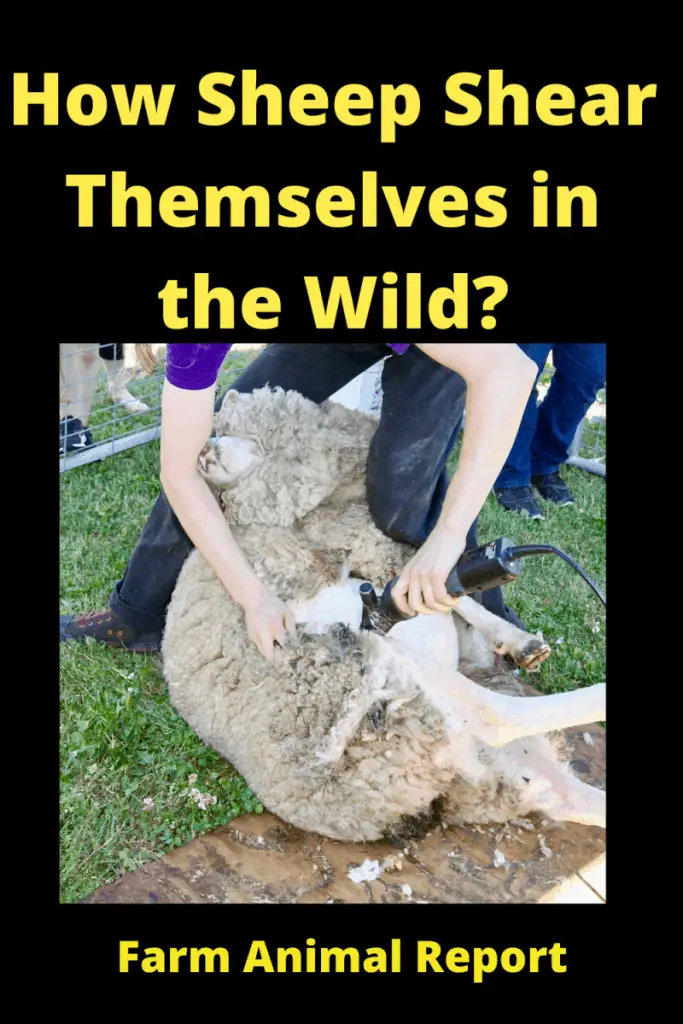

Shearing is the process in which the woolen fleece of sheep is cut off.

Shearer

The person removing the wool of sheep is called a shearer.

Shearing of Sheep

Typically, each adult sheep is shorn once each year. The annual shearing of sheep most often occurs in the shearing shed, a facility specially designed to process often hundreds and sometimes three thousand sheep per day.

Selectively Bred, Sheep are shorn in all seasons, depending on the climate, management requirements, and wool classer and shearers’ availability. Ewes are normally shorn before lambing in the warmer months, but consideration is typically made about the welfare of lambs by not shearing during cold climate winters.

However, in high region countries, pre lamb shearing encourages ewes to seek shelter among the hillsides, so that newborn lambs are not completely exposed to the elements. Shorn sheep tolerate frosts well, but young sheep especially will suffer in cold and wet windy weather.

In this event, they are shed every year until the weather clears. Some sheep may also be shorn with stud combs commonly known as cover combs, which leave more wool on the animal in colder months, giving greater protection.

Sheep shearing is considered sports all over the world with competitions held around. The competitions are usually held between spring and summer.

Modern Shearing

The large flocks of sheep are mustered, inspected, and possibly treated for parasites such as lice before shearing can start. Then they are shorn by professional shearing teams working eight hours a day, by machine shearing.

These contract teams comprise of shearers, shed hands, and a cook. Industry awards regulate Their working hours and wages. A working day starts at 7:30 and the day is divided into four runs of two hours each. “Smoko” breaks are a half-hour each, and a lunch break is taken n at midday for one hour.

Most shearers are paid on piece rate per sheep. Shearers, who “tally” more than 200 sheep per day, are called” gun shearers.” Typical mass shearing of sheep today follows a well-defined workflow

- Remove the wool

- Throw the fleece on to the wool table

- Skirt, roll, and class the fleece

- Place it in the appropriate wool bin

- Press and store the wool bin until it is transported.

Wool Removal

A sheep is caught by the shearer, from the catching pen, and taken to his stand on the shearing board. It is shorn using a mechanical handpiece. The wool is removed by following an efficient set of movements. Sheep struggle less using the tally-hi method, reducing strain on the shearer, and there is a saving of about 30 seconds in shearing each one.

The shearer begins by removing belly wool, separated from the main wool by a rouseabout, while the sheep are still being shorn.

A professional or gun shearer typically removes a fleece, without significantly marking or cutting the sheep, in two to three minutes, depending on the size and shape of the sheep. It is less than two minutes in competitive sheep shearing.

The shorn sheep is released and removed from the board via a chute in the floor or the wall to an exterior counting out a pen.

See Our Extensive Guide – 16 Ways to Make Money Sheep Farming

A Non-Mechanical Method of Sheep Shearing

This modern sheep method is not involving manual power and is also concerned with an injection. Only an injection of protein is being injected that creates a natural break in the wool fibers. After fitting a retaining net to enclose the wool, sheep are injected with protein.

When the net is removed after a week, the fleece has separated and is removed by hand. In some breeds, a similar process occurs naturally.

Fleece Skirting

Once the entire fleece has been removed from the sheep, the fleece is thrown, clean side down, on to a wool table by a shed hand. The wool tabletop consists of slats spaced approximately 12cm apart.

This enables short pieces of wool, the locks, and the debris, to gather beneath the table separately from the fleece. The fleece is then skirted by one or more wool rollers to remove the sweat ribs and other less desirable parts of the fleece.

The removed pieces largely consist of shorter seeded, burry or dusty wool, etc. which is still useful in the industry. As such, they are placed in separate containers and sold along with the fleece wool.

Other items removed from the fleece on the table, such as feces, skin fragments, twigs, and leaves, are discarded a short distance from the wool table not to contaminate the wool and the fleece.

Following the fleece skirting, it is folded, rolled, and examined for its quality in a process known as wool classing, which is performed by a registered and qualified wool classer. Based on its type, the fleece is placed into the appropriate wool bin ready to be pressed when there is sufficient wool to make a wool bale.

Roofing / Plucking Wool By Hand

In some primitive sheep, there is a natural break in the growth of wool in spring. By late spring, this causes the fleece to begin to peel away from the body, and it may be then plucked by hand without cutting- this is known as roofing. Individual sheep may reach this stage at slightly different times.

Problems Related to Shearing

Shearing the sheep brings us the wool, but there may be problems concerned with the shearing of sheep. It is a gentle process and must be performed humanely.

After the removal of the sheep’s wool, the sheep’s body coat is reduced, and it must be performed in the summer season so that sheep can survive and live without a coat of wool. Following are the problems that may expectedly arise during the shearing of the sheep

- Wrong time of shearing

- Rough handling

Wrong Time of Shearing

Sheep are sheared in the spring, just before they would naturally shed their wool coats. Because shearing too late would mean a loss of wool, most sheep are sheared while it is still too cold. An estimated one million sheep die every year of exposure after premature shearing.

Rough Handling of Sheep

Another problem with modern sheep shearing is that the shearers are not paid by the hour, but by the volume. They handle the animals very roughly, and a lot of sheep get injured.

The injuries may do more harm than good. Getting wool from the sheep is possible when sheep is alive and healthier. So humane and gentle handling of sheep must be carried to ensure the constant production of wool.

Shearing Devices

Whatever device is used, shearers must be careful to keep it clean to prevent the spread of disease amongst a flock.

Blade shearing has recently made a resurgence in Australia and the UK but mostly for sport rather than commercial shearing. Some competitions have attracted almost thirty competitors, and there have ever been shows created just for blade shearers to compete in.

Blade Shearers / No Electricity

Blade shears consist of two blades arranged similar to scissors except that the hinge is at the end farthest from the point. The cutting edges pass each other as the shearer squeezes them together and shear the wool close to the animal skin.

Blade shears are still used today but in a more limited way. Blade shears leave some wool on a sheep, and this is more suitable for cold climates such as Canterbury high country in the South Island of New Zealand, where approximately half a million sheep are still shorn with blade shears each year.

For those areas where no powered machinery is available, blade shears are the only option. Blade shears are more commonly used to shear stud rams.

Machine Shears

Machine shears, known as handpieces, operate similarly to human hair clippers in that power-driven toothed blade, known as a cutter, is driven back and forth over the surface of a comb and the wool is cut from the animal.

The original machine shears were powered by a fixed hand crank linked to the handpiece by a shaft with only two universal joints, which afforded a very limited range of motion. Later models have more joints to allow easier positioning of the handpiece on the animal. Electric motors on each stand have generally replaced overhead gear for driving the handpieces.

The jointed arm is replaced in many instances with a flexible shaft. Smaller motors allowed the production of shears in which the motor is in the handpiece. Professional shearers do not generally use these as the weight of the motor, and the heat generated by it becomes bothersome with continued use.

Holding Pens – How Did Sheep Survive before Shearing?

When the wool production of sheep declines, they are sold for slaughter. Millions of lambs and sheep are exported for slaughter each year.

Sheep Farming for Wool Profitability Table

| Sheep | Lambs / 3 Per Yr | Space Required 20 Sq Feet - Each | Grazing Acres .3 / Sheep | Feed Required / Yr $100 | 15 Lbs Wool / Year | Average Price $ 10 / LB Wool | Total Revenue Possible |

|---|---|---|---|---|---|---|---|

| 1 | 3 | 60 sq ft | .9 acres | $ 300 | 45 lbs | $ 450 | $ 150 |

| 2 | 6 | 120 sq ft | 1.80 acres | $ 600 | 90 lbs | $ 900 | $ 300 |

| 5 | 15 | 300 sq ft | 4.5 acres | $ 1,500 | 225 lbs | $ 2,250 | $ 750 |

| 10 | 30 | 600 sq ft | 9 acres | $ 3,000 | 450 lbs | $ 4,500 | $ 1,500 |

| 20 | 60 | 1200 sq ft | 18 acres | $ 6,000 | 900 lbs | $ 9,000 | $ 3,000 |

| 30 | 90 | 2,700 sq ft | 27 acres | $ 9,000 | 1,350 lbs | $ 13,500 | $ 4,500 |

| 40 | 120 | 4800 sq ft | 36 acres | $ 12,000 | 1,800 lbs | $ 18,000 | $ 6,000 |

| 50 | 150 | 3,000 sq ft | 45 acres | $ 15,000 | 2,250 lbs | $ 22,500 | $ 7,500 |

| 100 | 300 | 6,000 sq ft | 90 acres | $ 30,000 | 4,500 lbs | $ 45,000 | $ 15,000 |

| 200 | 600 | 12,000 sq ft | 180 acres | $ 60,000 | 9,000 lbs | $ 90,000 | $ 30,000 |

Sheep can Produce 2 - 30 lbs of wool per year depending on Breed

Raw washed Wool Runs $ 6 - $ 14 using average $ 10

Feed 5 Months Buying Hay $ 100 rest Grazing

Please Check my Numbers

Sheep Farming for Milk Profitability Table

| Sheep | Lambs / 3 Per Yr | Space Required 20 Sq Feet - Each | Grazing Acres .3 / Sheep | Feed Required / Yr $100 | Wool $ 15 lb / Year | Average Price $ 10 / LB Wool | 90 Gallon/ Yr each ewe | Price $ 30 per Gallon | Total Wool Revenue Possible | Total Revenue Milk and Wool |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 60 sq ft | .9 acres | $ 300 | 45 lbs | $ 450 | 270 | 8100 | $ 150 | 8,250 |

| 2 | 6 | 120 sq ft | 1.80 acres | $ 600 | 90 lbs | $ 900 | 540 | 16,200 | $ 300 | 16,500 |

| 5 | 15 | 300 sq ft | 4.5 acres | $ 1,500 | 225 lbs | $ 2,250 | 1350 | 40,500 | $ 750 | 41,250 |

| 10 | 30 | 600 sq ft | 9 acres | $ 3,000 | 450 lbs | $ 4,500 | 2700 | 81,000 | $ 1,500 | 82,500 |

| 20 | 60 | 1200 sq ft | 18 acres | $ 6,000 | 900 lbs | $ 9,000 | 5400 | 162,000 | $ 3,000 | 165,000 |

| 30 | 90 | 2,700 sq ft | 27 acres | $ 9,000 | 1,350 lbs | $ 13,500 | 8100 | 243,000 | $ 4,500 | 247,500 |

| 40 | 120 | 4800 sq ft | 36 acres | $ 12,000 | 1,800 lbs | $ 18,000 | 10,800 | 324,000 | $ 6,000 | 330,000 |

| 50 | 150 | 3,000 sq ft | 45 acres | $ 15,000 | 2,250 lbs | $ 22,500 | 13,500 | 405,000 | $ 7,500 | 412,500 |

| 100 | 300 | 6,000 sq ft | 90 acres | $ 30,000 | 4,500 lbs | $ 45,000 | 27,000 | 810,000 | $ 15,000 | 825,000 |

| 200 | 600 | 12,000 sq ft | 180 acres | $ 60,000 | 9,000 lbs | $ 90,000 | 54,000 | 1,620,000 | $ 30,000 | 1,650,000 |

Sheep can Produce 1/2 Gallon Milk per day / 180 Day Lactation

Raw Sheep Milk $9 - $25 per Quart - Used $ 30 per Gallon for Table

Feed 5 Months Buying Hay $ 100 rest Grazing

Please Check my Numbers

18 Breeds of Hair Sheep FAQ Table

| Hair Breeds of Sheep | Country Origin | Purpose of Breed | Use | Ewe Weight |

|---|---|---|---|---|

| Katahdins | Caribbean / Maine / Africa | To Graze Power lines / instead of Chemicals | Meat | 120 - 160 lbs |

| Dorper | South Africa | Thrive in Africa / Hot Climate | Meat / Fast Growing | 230 LBs |

| Blackbelly | America | Hot Climates | Meat | 150 LBs |

| St. Croix | Carribean | Came on Ships for Meat for sailors | Meat | 150 lbs |

| Romanovs | Russia | Primarily for Meat | Meat Wool - Double Coated | 110 lbs |

| Blackhead Persian | Africa / Somaila | Bred for High Quanity of Fat | Meat | 120 lbs |

| West African Dwarf | South / Central Africa | Meat | 55 lbs | |

| Red Maasi | East Africa | Bred for Hardiness and parasite Resistance | Meat | 77 Lbs |

| Wiltshire Horn | England | Do not suffer from Flystrike | Meat | 149 lbs |

| Royal White | United States / Texas | Bred for Tender Meat and Disease Resistants | Meat | 175 lbs |

| California Red | Not completely Hair sheep/ Combination of both/ Prod 2 lambs Yr | Meat | 140 lbs | |

| Damara | Egypt | Vigorous with fast growing / in extreme conditions | Meat | 110 lbs |

| Pelibuey | Cuba / Mexico | Tropical Sheep | Meat | 75 lbs |

| Africana | Columbia / Venezula | Meat | 110 lbs | |

| Morada | Brazil | Survive Scrub | Meat | 66 lbs |

| Brazillian Somaila | South Africa / Somali | Meat | ||

| Uda | Africa | Long Legged Sheep | Meat | 88 lbs |

| Touabire | Africa | Dairy / Meat | 77 lbs |

Minature Breeds of Sheep

| Breed | Height | Weight / Full Grown | Food Per Day | Lifespan | Wool / Hair Sheep | Cost |

|---|---|---|---|---|---|---|

| Quessant Sheep | !8" | 28 - 30 Lbs | 1/2 - 1lb | 10 - 12 Yrs | Wool | $ 350 - 450 |

| Baby Doll Southdown | 18" | 75 lbs | 2 - 3 Lbs | 10 - 12 Yrs | Wool | $ 350 -450 |

| Southdown Sheep | 18" - 24" | 130 lbs | 6 - 6 lbs | 10 - 12 Yrs | Wool | $ 180 - $ 600 |

| Cheviot Sheep | 20" | 130 Lbs | 6 - 6 lbs | 10 - 12 Yrs | Wool | $ 180 - $ 600 |

| Border Cheviot | 20" | 130 lbs | 6 - 6 lbs | 10 - 12 Yrs | Wool | $ 180 - $ 600 |

| Shetland Sheep | 24" | 75 - 100 lbs | 6 - 6 lbs | 10 - 12 Yrs | Wool | $ 50 - $100 |

| Navajo - Churro | 20" | 110 lbs | 6 - 6 lbs | 10 - 12 Yrs | Wool | $ 200 |

Amount of Food they Need

Lifespan

Wool - They Need to be Sheared Hair Sheep - Do not Grow Woll but shed Hair once a year

Pricing Depend whether you just want Sheep Or you want to Breed

Toxic Plants for Sheep Pastures

| Toxic / Poisonous Plant | Symptoms / Characteristics |

|---|---|

| Garden Iris | Roots and stems |

| Holly | Berries - Diarrhea - vomiting - stupor |

| Morning Glory | hallucinogenic seeds |

| Rhubarb | Leaves - Convulsions and Death |

| Wild Cherry | Wilted Leaves have Cynaide - Convolusions, Rolling Eyes, Tongue hanging, animal dies within hours |

| Yew | Needle Like Shrub - vomiting, convulsions, animals Rarely survive this poisoning |

| Oaks | Acorns, young trees - anorexia, constipation diahreah thirst gastro problems |

| Mountain Laurel | Same symptoms of Poiaoning. Vomiting, Diahreah, salivation - Usually fall into Coma and then Death |

| Rhododendron | Same symptoms of Poiaoning. Vomiting, Diahreah, salivation - Usually fall into Coma and then Death |

| Azalea | Same symptoms of Poiaoning. Vomiting, Diahreah, salivation - Usually fall into Coma and then Death |

many of these are found around Fence Rows

Fields Should be Checked

Sheep Associations 10 Breeds of Sheep

| Breeds of Sheep | Country Origin | Purpose of Breed | Use | Ewe Weight | Association For Info |

|---|---|---|---|---|---|

| Suffolk Sheep | Britian / Suffolk | Fast Growing | Meat | 250 - 350 Lbs | United Suffolk Sheep Association |

| Merino Sheep | Spain | Softest Wool | Wool | 100 - 200 Lbs | American and Delane Merino Sheep Association |

| Hampshire | Britain | Best Tasting Mutton | Wool / Meat | 200 Lbs | American Hampshire Sheep Association |

| Romney | England / Romney Marsh | Disease Resistance | Wool / Meat | 225 - 275 Lbs | American Romney Breeders Association |

| Lincoln Sheep | England | Produce Longest Fleece In World | Wool | 250 - 350 Lbs | National Lincoln Sheep Breeders Association |

| Dorper Sheep | South African | Fast Growing Meat | Meat | 230 Lbs | American Droper Sheep association |

| Turcana Sheep | Romainia | Adapted Alpine Pasture | Wool / Milk / Meat | 175 - 200 Lbs | ? |

| Rambouilette Sheep | France | Strong / Hearty / All Climates | Wool / Meat | 300 Lbs | American Rambouilette Sheep Breeders Association |

| Leicester Longwool | United Kingdom | Fast growing / Good Fleece | Wool | 200 Lbs | Leicester Longwool Sheep Breeders Association |

What Areas of the World do Wild Sheep Live?

Wild Sheep live in a number of different areas throughout the world. Some of these include:

- The Rocky Mountains in North America

- The Andes Mountains in South America

- The Alps in Europe

- The Himalayas in Asia

- Australia and New Zealand

How High Altitudes can wild sheep live?

Sheep can live comfortably at altitudes as high as 16,000 feet.

Some of the predators that wild sheep have to be aware of include:

- Wolves

- Coyotes

- Bears

- Mountain lions

- Bobcats

Where are Wild sheep in Northern Mexico?

The Wild Sheep in Mexico are found in the Sierra Madre Occidental range. This area is located in the northwestern part of the country.

The species of wild sheep that live in this area are:

- Ovis canadensis nelsoni (Rocky Mountain bighorn sheep)

- Ovis canadensis auduboni (Desert bighorn sheep)

Where is Wild Sheep in North America?

The Wild Sheep in North America are found in the Rocky Mountains. This mountain range goes from New Mexico all the way up to Canada.

The species of wild sheep that live in this area are:

- Ovis canadensis nelsoni (Rocky Mountain bighorn sheep)

- Ovis canadensis auduboni (Desert bighorn sheep)

- Ovis dalli stonei (Dall’s Sheep)

What is the difference between a Bighorn Sheep and a Dall’s Sheep?

Bighorn sheep have horns that curl back and away from their face, while Dall’s sheep have horns that go straight up and then curve slightly inward at the tips. Both male and female bighorn sheep have horns, but only the males have horns on Dall’s sheep.

What do Wild Sheep Eat?

Wild sheep are herbivores and their diet consists mostly of grasses, sedges, forbs, and shrubs. They will also eat lichens and mosses if they are available. In winter when food is scarce, they have been known to eat bark from trees.

Where is Wild Sheep in Central Europe?

The Wild Sheep in Europe are found in the Alps. The Alps are a mountain range that goes through Austria, Germany, Italy, and Switzerland.

The species of wild sheep that live in this area are:

- Ovis canadensis musimon (Alpine ibex)

- Ovis orientalis (Asiatic mouflon)

- Ovis ammon (Aoudad or Barbary sheep)

Do all Wild Sheep have Horns?

No, not all wild sheep have horns. There are two species of wild sheep that do not have horns and they are:

- Ovis ariseDom (estic sheep)

- Capra hircus (Goat)

What are the most Common Breeds of Wild Sheep

The Most Common Breeds of Wild Sheep are:

- Ovis aries (Domestic sheep)

- Ovis canadensis (Bighorn sheep)

- Ovis dalli (Dall’s sheep)

- Ovis Musimon (Alpine ibex)

- Capra hircus (Goat)

What is the Difference between Bighorn Sheep and Mountain Goats?

The difference between bighorn sheep and mountain goats is that bighorn sheep have horns that curl back and away from their face, while mountain goats have horns that go straight up.

Both male and female bighorn sheep have horns, but only the males have horns on mountain goats. Another difference is that mountain goats are more sure-footed and agile, while bighorn sheep are not as agile but can run faster.

What is the Difference between a Domestic Sheep and a Wild Sheep?

The difference between a domestic sheep and a wild sheep is that domestic sheep have been bred to be docile and easy to handle, while wild sheep are much more timid and skittish.

Domestic sheep also have wool that is softer and finer, while wild sheep have coarser wool. Lastly, domestic sheep come in many different colors due to breeding, while wild sheep usually only come in shades of brown or white.

How can Wild Sheep live in Rugged Terrain?

Sheep can live easily in rugged terrain because of their sure-footedness. They have split hooves that give them traction on steep and rocky terrain. They also have a coat of wool that protects them from the elements.

What is the Life Cycle of a Wild Sheep?

A wild sheep’s life cycle consists of birth, growth, reproduction, and death. Birth usually occurs in the springtime after a gestation period of five to six months. The lamb will stay with its mother for several months until it is old enough to fend for itself.

After about two years, the sheep will be fully grown and ready to reproduce. The average lifespan of a wild sheep is ten to twelve years in the wild, but they can live up to twenty years in captivity.

Do Wild Sheep live in a Desert Environment?

Some breeds of Sheep have acclimated to the Desert environment by growing a coat of fine, short hair that helps protect them from the sun and heat.

They also have longer legs than other breeds of sheep which helps them to travel long distances in search of food and water. The most common breed of desert sheep is the Barbary Sheep.

What Wild Sheep live in Desert Mountains

The Barbary sheep is the most common breed of desert sheep. They are native to the Barbary Coast of North Africa and were introduced to the deserts of the southwestern United States in the early 1900s.

The main Types of Wild Sheep are?

The Main Types of Wild Sheep Hunters Hunt Today are;

- Ovis canadensis (Bighorn Sheep)

- Ovis Dalli (Dall’s Sheep)

- Capra hircus (Mountain Goat)

What is the Best Way to Hunt Wild Sheep?

The best way to hunt wild sheep depends on the type of sheep you are hunting. If you are hunting bighorn sheep, the best way is to stalk them and get as close as possible before taking a shot.

Dall’s sheep are most often hunted by spot and stalk, as they are very wary and difficult to approach. Mountain goats are usually hunted by spot and stalk as well, although sometimes they can be lured in with bait.

What is the Best Time of Year to Hunt Wild Sheep?

The best time of year to hunt wild sheep depends on the type of sheep you are hunting. Domestic sheep can be hunted year-round, but the best time is in the fall when they are getting ready for winter and their coats are at their thickest.

Bighorn sheep can be hunted in the late summer or early fall when they are finishing their rutting season and their horns are at their fullest. Dall’s sheep can be hunted in the spring or early summer when they are shedding their winter coats. Mountain goats can be hunted year-round, but the best time is in the fall when they are getting ready for winter and their coats are at their thickest.

What is the Best Way to Cook Wild Sheep?

The best way to cook wild sheep depends on the type of meat you are cooking. Domestic sheep meat is best cooked slow and low, either in a crockpot or oven. Bighorn sheep meat is best cooked quickly, either grilled or roasted. Dall’s sheep meat is best cooked slowly, either in a crockpot or oven. Mountain goat meat is best cooked quickly, either grilled or roasted.

The majority of Modern Sheep is what Breeds?

Todays most popular breeds of Domestic Sheep Are;

- Merino

- Rambouillet

- Coopworth

- Dorset

- Hampshire

What is the Purpose of Sheep in Today’s World?

The majority of sheep in the world are used for their wool and meat. Sheep wool is used to make clothing, blankets, and other textiles. It is also used as insulation in homes and buildings.

Sheep meat is consumed by people all over the world and is a popular choice for those who do not eat red meat. Lamb, which is the meat of a young sheep, is especially popular in Mediterranean and Middle Eastern cuisine.

How do Sheep Farmers use Selective Breeding for Wool Production?

Today sheep farmers use scientific methods of selective breeding to produce animals with desirable traits such as high-quality wool, rapid growth rates, and docile dispositions. By carefully selecting which animals to breed, farmers can produce offspring that are more likely to have the desired characteristics. This process is called artificial selection.

Do Sheep Have Year-Round Wool Growth?

A sheep’s wool grows continuously, but the rate of growth varies with the seasons. In the spring and summer, when the days are longer and there is more sunlight, the wool grows more quickly. In the fall and winter, when the days are shorter and there is less sunlight, the wool grows more slowly.

The majority of Sheep in the World are in What Country?

The sheep Population by the First World countries is approximately:

- Australia- 74,000,000

- New Zealand- 40,000,000

- United Kingdom- 26,500,000

- China- 20,700,000

In general, the top wool-producing countries are also the countries with the largest sheep populations. This is because there is a higher demand for wool in these countries.

Australia and New Zealand produce the majority of the world’s wool because they have large sheep populations and mild climates that are conducive to year-round wool growth.

China produces a significant amount of wool as well, despite having a smaller sheep population than Australia and New Zealand. This is because Chinese farmers use selective breeding practices to produce animals with high rates of wool growth.

Is Sheep Wool Waterproof?

Sheep wool has the following characteristics;

- It is absorbent

- It is insulating

- It is fire resistant

- It is water-resistant

The waterproofing properties of sheep wool are due to the presence of lanolin. Lanolin is a fatty substance that coats each individual wool fiber. This coating helps to repel water and dirt, and it also makes the wool more flexible and less likely to break. In addition, lanolin helps to protect the skin from chafing and other irritations.

How Often do Sheep need Regular Shearing?

Domestic sheep are generally sheared once a year, in the springtime. This is because the wool grows more quickly in the warmer months and because the sheep do not need the insulation of their wool in the summertime. However, some farmers shear their sheep more frequently, depending on the needs of the animals and the market for wool.

What Are Some Common Health Problems for Sheared Sheep?

The most common health problems for sheep are parasites, pneumonia, and foot rot. Parasites can live on the skin or inside the body of a sheep and cause itching, hair loss, and poor growth.

Pneumonia is a viral respiratory infection that causes coughing, difficulty breathing, and fever. Footrot is a bacterial infection that affects the hooves and can cause lameness.

Sheep farmers take steps to prevent these health problems by providing clean housing, good nutrition, and regular veterinary care. In addition, they often use parasite control products such as wormers and insecticides.

Do Wild Sheep Need to be Sheared?

No, wild sheep do not need to be sheared. They shed their wool naturally in the springtime. This process is called molting. Molting helps the sheep to regulate their body temperature and get rid of any damaged or dirty wool fibers.

How are Electric Motors used in Sheep Shearing?

the different Methods of Sheep shearing are done by hand, by machine, or a combination of both. The most common method of sharing is done with an electric motor.

Electric shears are much faster than hand shears and can sometimes be used to shear multiple sheep in one day. However, they can be more expensive to purchase and maintain.