Sheep Farming for Wool. One of the major Farms across the world is Sheep farm. Sheep are Bred and Raised for the amount of Wool they can Produce. These animals are sheared and then their Valuable Raw Wool is Sold to be used in clothing to be made into cloth, and also in the furniture Industry. Here it is used in the fabrication of chairs and upholstery.

Sheep Farming for Wool & Profit

There are three Methods for Farming Sheep in today’s farming Market. Sheep are used for

- Wool

- Milk

- Meat

We will be learning about Raising Sheep for the Wool Market Today. Sheep Wool grows just like our human Hair. When it attains a certain length. Sheep shearing is a craft that has to be learned. The many States have schools where this can be taught. There seems to always be a shortage of sheep shearers. An experienced person can shear an average sheep in around two minutes. The world’s Record for shearing a sheep is currently 37.9 seconds.

In Australia, Lou Brown set a world record for shearing Merino Ewes sheared in 8 hours. He sheared 497 ewes in 8 Hours on April 27, 2019, that is just over one sheep per minute.

The process that is involved in getting wool from its owner to the market is very interesting. These are the steps it takes in the Journey

Here is a Sheep Farming Profitability – The Largest Cost we included was the cost for feed, assuming it needed to be purchased in the Winter. But if a Farm can produce its own Feed that would have a great impact on Profitability

How Much is Sheep Wool Worth

Sheep Farming for Wool Profitability Table

| Sheep | Lambs / 3 Per Yr | Space Required 20 Sq Feet - Each | Grazing Acres .3 / Sheep | Feed Required / Yr $100 | 15 Lbs Wool / Year | Average Price $ 10 / LB Wool | Total Revenue Possible |

|---|---|---|---|---|---|---|---|

| 1 | 3 | 60 sq ft | .9 acres | $ 300 | 45 lbs | $ 450 | $ 150 |

| 2 | 6 | 120 sq ft | 1.80 acres | $ 600 | 90 lbs | $ 900 | $ 300 |

| 5 | 15 | 300 sq ft | 4.5 acres | $ 1,500 | 225 lbs | $ 2,250 | $ 750 |

| 10 | 30 | 600 sq ft | 9 acres | $ 3,000 | 450 lbs | $ 4,500 | $ 1,500 |

| 20 | 60 | 1200 sq ft | 18 acres | $ 6,000 | 900 lbs | $ 9,000 | $ 3,000 |

| 30 | 90 | 2,700 sq ft | 27 acres | $ 9,000 | 1,350 lbs | $ 13,500 | $ 4,500 |

| 40 | 120 | 4800 sq ft | 36 acres | $ 12,000 | 1,800 lbs | $ 18,000 | $ 6,000 |

| 50 | 150 | 3,000 sq ft | 45 acres | $ 15,000 | 2,250 lbs | $ 22,500 | $ 7,500 |

| 100 | 300 | 6,000 sq ft | 90 acres | $ 30,000 | 4,500 lbs | $ 45,000 | $ 15,000 |

| 200 | 600 | 12,000 sq ft | 180 acres | $ 60,000 | 9,000 lbs | $ 90,000 | $ 30,000 |

Sheep can Produce 2 - 30 lbs of wool per year depending on Breed

Raw washed Wool Runs $ 6 - $ 14 using average $ 10

Feed 5 Months Buying Hay $ 100 rest Grazing

Please Check my Numbers

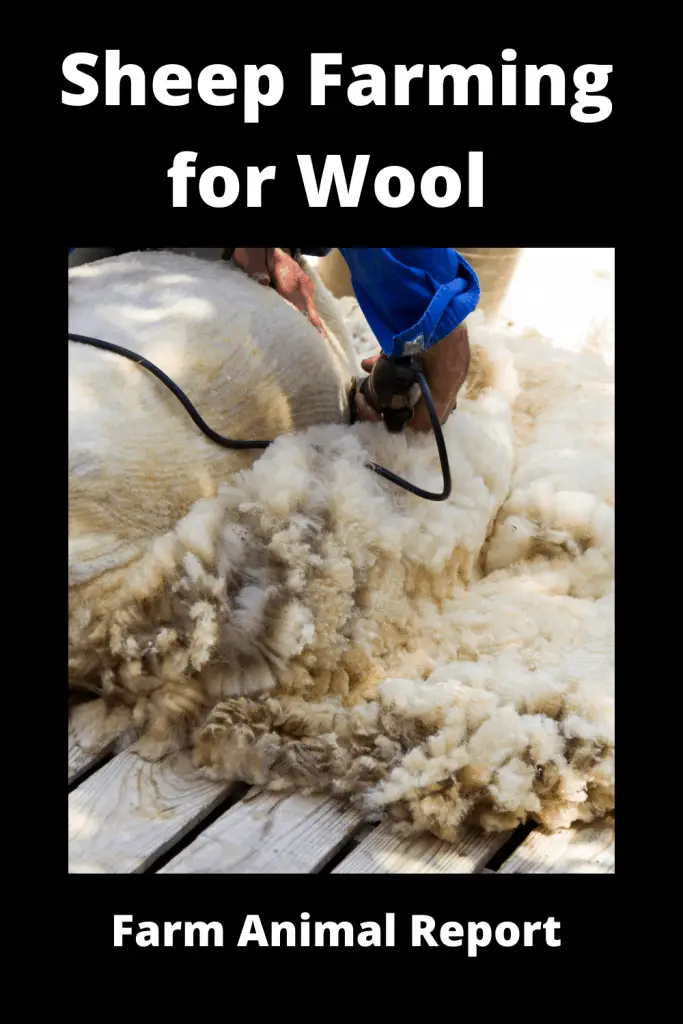

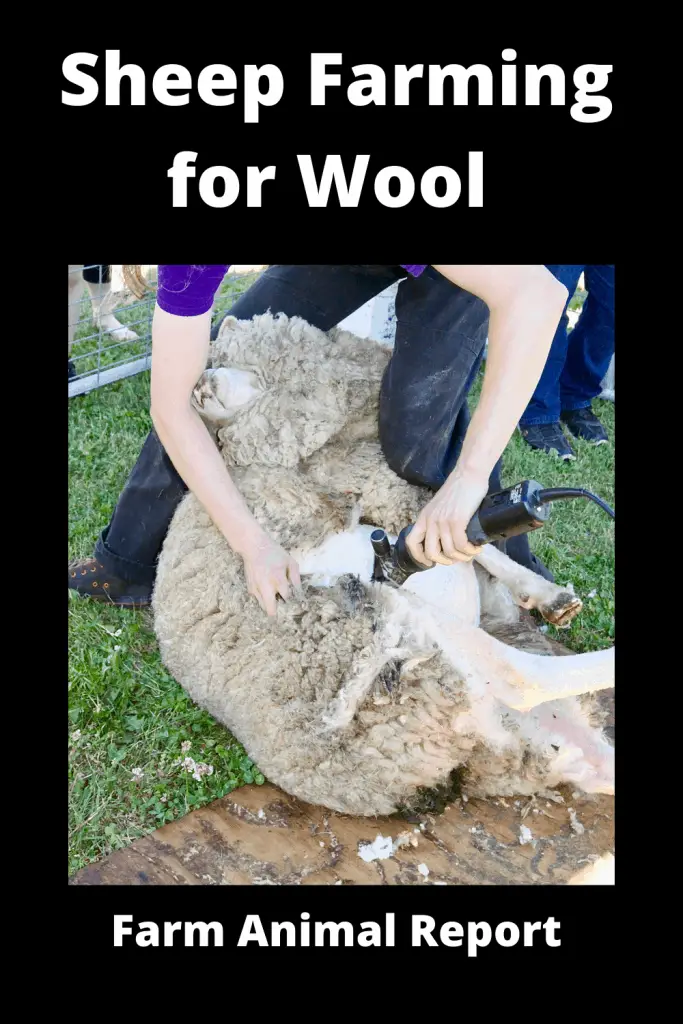

Sheep Shearing

Sheep are sheared twice a year. It is planned so they will have enough wool for warmth in the winter. Usually in March and then they are sheared prior to Lambing.

Sheep Wool Cleaning

the fleece ( Sheared Wool) is washed, any solids grasses are picked from it. It then is washed and dried. If it is not done properly it can render the fleece unusable

Scouring Sheep Wool

Contaminants Soil, vegetable in the fleece, some greasy in nature. Need to be removed from the fleece. The fleece is passed through a machine, a washing machine if you will, it contains eight different bowls/washes / that clean the wool. These contain, detergents, water, alkali, and organic solvents to clean the fleece.

Grading Sheep Wool

Grading Sheep Fleeces in three major Methods

- Blood System – This is the Oldest Method of Grading going back to the old colonial Days in the United States. This Grading method is based on the Bloodlines of the Sheep Fleeces

- Count System – This system is more detailed and it is gauging how many Yanks can be made from the wool. A yank equals 560 Yards. A system of Length

- Micron System – This is the most detailed system of grading and is determined by the thickness of the wool fiber. The wool is separated into other grades according to their individual thicknesses.

See Our Extensive Guide – 16 Ways to Make Money Sheep Farming

Sorting Wool

Sorting is a manual method done by hand. Where workers with a very good sense of touch sort the wool by how fine it feels, then also by its color, and then by its length.

Carding Wool

The Process of carding is where the wool is stretched by a series of Brushes. So that it can then be used for yarn. It is done by machine, but it untangles, cleans, and then intertwines the fibers to make them usable.

Spinning Wool

After the wool fibers have been Carded they are then spun together by a machine. These fibers are then spun into usable yarn. In the olden days wool was spun by hand and prepared for use. Today automated machines are used. the process is very efficient and fast.

Weaving Your Wool

Weaving the wool is usually done on a loom. this is a device that allows you to interweave fibers in a Right angle pattern. This is the process where the wool fiver is now made into cloth. These right-angle patterns allow them to for a strong material suitable to clothes, draperies, and similar cloth products. This interlocking pattern that is used is called the weave.

Finishing The Wool

After the weaving process, the next step is finishing. It is a Multi-step process to completely set it in permanently. The following steps are

- Fulling – is where the fabric is immersed in water to give set to interlock

- Crabbing – Permanently sets the interlock

- Decating – Shrink Proofing

- Dyeing – Giving The Fabric its final Color

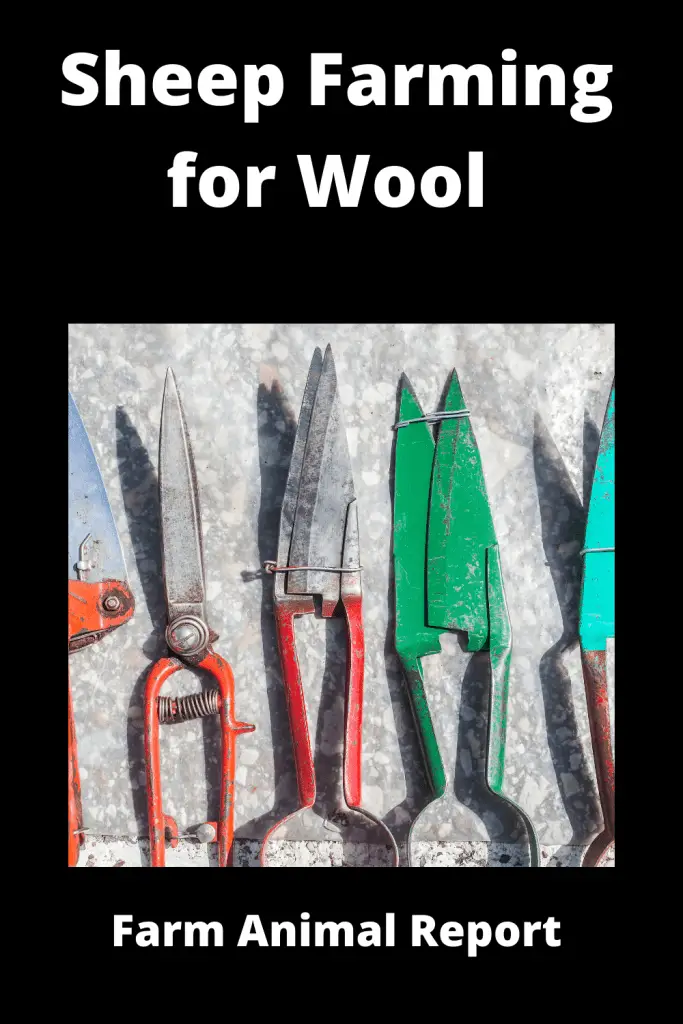

Types of Sheep Shearing Tools

There are two types of Shearing tools that are used in removing the wool from the sheep.

- Blade Shears – Very Sharp Long Blade scissors that will cut through the wool and separate it from the sheep

- Machine Electric Shears – Most are using these – they are like a heavy-duty set of hair clippers. They can take and give it a sheep haircut. Very quickly separating the Fleece from the sheep. It is painless for the sheep.

The Process for Shearing is as described here. Again it is a very fast process. This process has not been automated yet apart from – electric shears – here are the steps

- Shear off the Fleece ( Shears or Clippers )

- Throw the Fleece on the Wool Table

- Skirt, Roll and Class the Fleece

- Move it to the appropriate Wool Bin

- Press and store the wool until Transport.

Sheep Dipping for Insect Control

A Sheep dip is basically a bath in the configuration that the sheep are submerged in a solution that will kill Parasites. It protects the wool at the same time it kills any Fleas, Ticks, Itch Mites, and Lice. The solution is some kind of insecticide and also a fungicide.

History takes it back to the 1830s where they dipped the sheep in mild forms of Arsenic Dip.

Many times they have a concrete tank that the sheep are led through so that they will be completely submerged. And their wool is completely saturated so that it will get to all insects. They keep their heads up but the rest of the animal is completely put under.

How Much Wool does a Breed of Sheep Produce

Sheep produce different amounts of Wool compared to the Breed of Sheep it is.

| Breed Of Sheep | Lbs of Fleece |

|---|---|

| Columbia | 12 – 16 lbs |

| Icelandic | 4 – 5 lbs |

| Lincoln | 12 – 16 lbs |

| Polypay | 7 – 10 lbs |

| Rambouillet | 10 – 15 lbs |

| Romney | 10 – 18 lbs |

| Shetland | 2 – 4 lbs |

| Southdown | 5 – 8 lbs |

| Suffolk | 4 – 8 Lbs |

| Traghee | 10 – 14 lbs |

| Shropshire | 9 – 11 lbs |

How Often do you Shear a Sheep – What is it Worth

Usually, Sheep farmers shear sheep twice a year. One in the Spring and just before lambing. Rams are sheared in Spring also and they usually have more wool. Some breeds produce even more wool and need to be sheared twice a Year.

The Value of The Fleece is gauged on three things, Bloodlines of Sheep, Length of the Wool, and then the thickness of the fiber. Our Table we calculated on $ 10, But we found Prices of raw wool from $ 6.00 – $ 14.00 Lb

How Many Sheep Can you Shear in a Day

The world record was shearing a sheep in 37.9 seconds. But that was in Perfect settings. Generally 2 – 3 Minutes per Sheep. If you are looking in a day a single shearer can shear approximately 200 Sheep.

How Many Times a Year can you Shear Sheep

Most Breeds you can shear once per year. There are other Breeds that you need to shear twice a year. It all depends on the speed at which the hair grows. I am sure it could be closely tied to nutrition. From a Farm Production Study, it would be an interesting study to see what factors of Nutrition affect the speed of wool growth.

Will a Sheep Die if it is not Sheared

Yes, Most Sheep are unable to Shed. If they are not sheared several things can happen. They can die from Overheat – Insect Infection can become critical. They also can become immobilized by their great size because of their Wool. Making them easy prey for Predators

Does Shearing Hurt Sheep

No, Technically it does not cause them any pain, but sheep are easily stressed, and if the shearer accidentally cuts them while shearing would cause them some anxiety. Shearing them is no different than us getting a Haircut.

What is Bioclip – Removing Wool without Shearing

Bio clip is a Wool Harvesting Method for chemically removing the Wool off of the sheep without the actual physical Process of Shearing. This is how it works

- Animals are fitted with wool retaining Net

- Given 1 injection of Epidermal Growth Factor (EGF)

- 1 A week later The Fleece falls off the animal into the net.

- Removed bt hand called Doffing

- EGF Dissipates Quickly and Hair Regrowth restarts to regrow normally 24 hours after vaccination

- Sheep can be sold 7 days after Wool Removal

- Eliminates second cuts, and pieces of Skin in Fleece

- Reduces the Need of Chemicals for Parisite Control

Shearing Sheep before Lambing / Breeding

Shearing Sheep farmers have found to greatly increase farm productivity. Here are some of the reasons for this

- farmers shear 30 – 45 Days before Lambing

- Increases Blood Flow to the Lamb

- No wool stimulates Ewes to find shelter to stay warm – this results in many more lambs being born inside

- Females eat more after Shearing – which increases the health of Mother and lamb.

- If Ewes are Sheared creates a Dryer environment inside the Barns

- Creates a cleaner environment for lambs be born

- Also, the stress of lambing creates a break in the wool fibers which slightly reduces their value.

Sheep Pest / Bug infestations / Parasites

here are some of the External Pests that afflict Sheep which can affect the quality of the wool. Here are some of the Big Ones

- Ticks / Sheep Keds – They feed on Blood. They can be transferred animal to animal contact. The Lay eggs under the sheep’s skin. The Larva crawls out and about 3 weeks later flys off. This can cause blemishes in the Fleece. These blemishes are called cockles. – They are controlled with Insecticide and sprays.

- Sheep Nose Bots – These are large flies that are the size of Bumblebee. The lay Eggs on the sheep near its nostrils. When the eggs hatch the larva crawl up the sheep’s nostrils and live in the nasal cavity feasting on Mucous. This causes the Sheep to be susceptible to sneeing, and nasal infections. research has shown that 90% of Sheep in Kentucky have them during the months of October to February. – They are controlled by Insecticide solutions

- Fleeceworms – These are most common around flesh wounds from a fence or possibly Birthing. They also can become infected when feces is stuck in the anal section and becomes putrid. The Flys lay their eggs and they hatch as maggots and can heavily be infested if Not Treated. In bad infestations, they can attack the skin and cause wool to fall off the sheep

- Mites – Called the Sheep Itch Mite. This mite spreads slowly usually in winter. It is passed by physical Contact

- Lice – live their whole lifespan in sheep’s wool. They are passed sheep to sheep by physical contact.

Sheep Wool Diseases

- Foot Rot / Foot Scald – caused by a bacteria cand also be found in goats and cattle, deer and horses. can result in lameness, animals often lay around a lot damaging their wool. See Pics in This link

- Caseous lymphadenitis – This is a bacteria that causes the sheep lymph nodes to swell – abscess have an onion ring appearance

- Lumpy Wool – Disease caused by a bacteria can cause the skin to lift off taking wool with it.

Sheep Worms / Internal Parasites.

These are some of the worms that Sheep are susceptible to Getting

- Lung Worms – they are passed out of infected sheep through feces. The Larva then are ingested by other Sheep. They mature and live in the sheep’s lungs. The symptoms are coughing, fever, nasal Discharge, and rapid breathing. Rarely Fatal

- Stomach Worms

- Liver Flukes – live in the sheep’s liver. Their fist host is snails. can cause death in the Sheep

- Coccidia – This is evident when in large numbers by diarrhea in the sheep. Signs also include Fever, a wool break can result in Death

- Tape Worms – Are spotted in sheep feces. It is thought that they harm the sheep in effect of stealing nutrients to the sheep and possibly the lambs that are born

- Deer or Brain Worm – this worm has a native host of the White-Tailed Deer. Its first Host is a snail that can be ingested by the sheep. The worm takes up residence in the brain causing fatal damage if the infestation is heavy. Best is prevention keeping sheep away from swampy snail environments.